deviceWISE® EDGE

An integration and enablement platform for managing your industrial IoT (IIoT) solutions without custom code.

Smart manufacturing drives greater efficiency and productivity in manufacturing across industries. This digital transformation’s backbone consists of industrial Internet of Things (IIoT) systems.

IIoT platforms integrate traditional IT functions with those of operational technology (OT) to transform factory floor operations. These platforms integrate legacy machines and sensors into IT systems and introduce edge intelligence. 5G accelerates this transformation by eliminating cabling and enabling ultra-reliable, mission-critical wireless communications.

Smart factories create efficiencies and capabilities that help manufacturers improve productivity and identify revenue opportunities. Real-time overall equipment effectiveness (OEE) visualization tools offer data collection and transformation. They provide full visibility into your factory’s efficiency.

Monitor the condition and performance of connected machines and assets to improve asset availability and performance. Sensors on factory equipment transmit critical data regarding equipment health and utilization. This feedback helps manufacturers maximize equipment uptime and avoid operational disruptions.

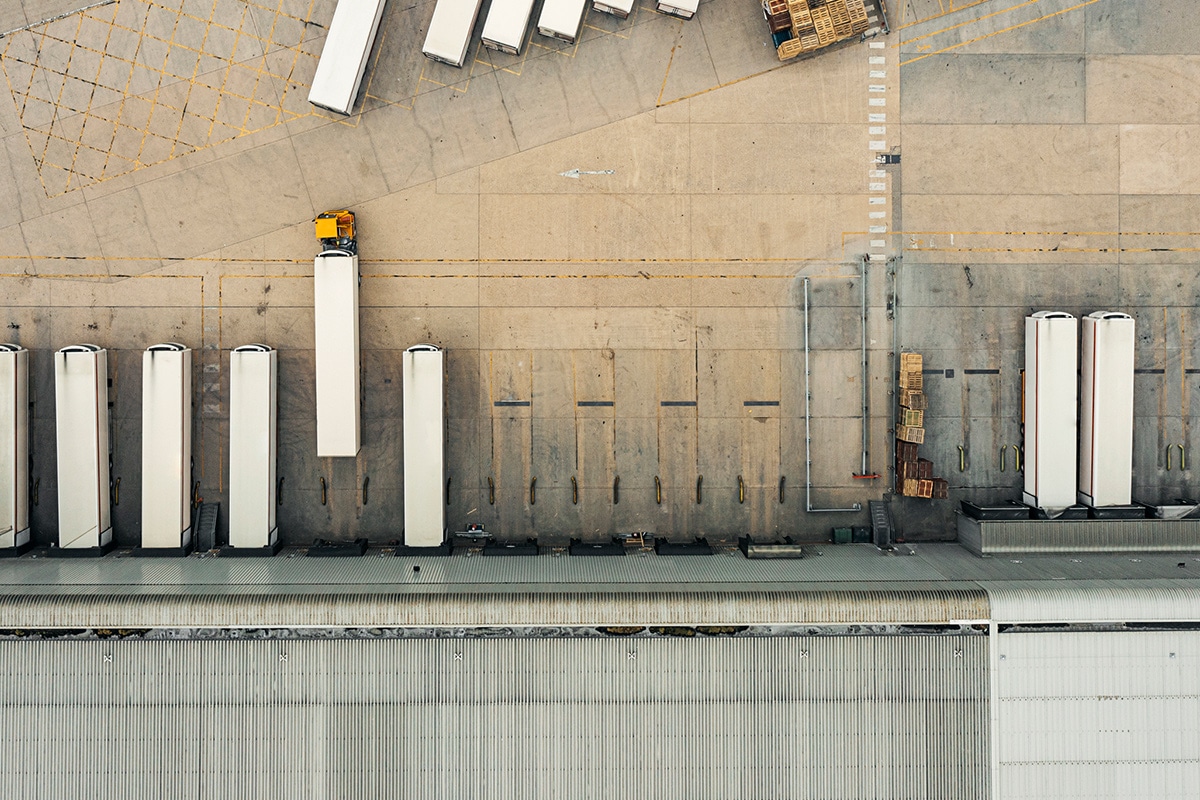

Supply chain management requires end-to-end visibility of raw materials and finished goods at all production and delivery stages to be effective. IIoT supply chain management solutions enable production managers and suppliers to better manage assets and inventory to meet demand.

An integration and enablement platform for managing your industrial IoT (IIoT) solutions without custom code.

Build your IoT solution efficiently with instant access to tools and resources to accelerate your IIoT deployment.

Visualize and analyze your machine data with custom dashboards and HMIs, without writing custom code.

What Is Industry 4.0?

Industry 4.0 (the Fourth Industrial Revolution) is the next step in the evolution of technology in industry. In the last century, manufacturing technology progressed from Henry Ford’s assembly line to computerization — taking physical data and digitizing it. Then automation was introduced. Now, with Industry 4.0, value is being added through artificial intelligence (AI) and analytics.

How Does the Smart Factory Improve Quality Control?

When it comes to the smart factory, manufacturers need solutions that provide vertical and horizontal integration. This integration makes it easier to connect the factory to inbound and outbound supply chains. Our IIoT data orchestration, device management and enterprise system integration solutions are suited to all manufacturing verticals, including:

Learn how to connect your enterprise and IoT applications without custom code.

IoT Condition Monitoring

Condition monitoring involves measuring variations in indicators, such as:

This IoT-enabled monitoring provides insight into connected devices’ performance, health and status. Leveraging condition monitoring helps manufacturers improve resource utilization and prevent unplanned downtime.

Condition monitoring helps determine improvement areas, identify potential problems and take the necessary actions before issues occur. Manufacturers can prevent damage and reduce maintenance costs with IoT-enabled condition monitoring solutions.

How IoT-Enabled Condition Monitoring Works

We’ve pioneered IoT products and solutions for over 20 years. Speak with our IIoT experts today to learn how we can help with smart factory transformation.