How the IIoT Opens New Frontiers of Remote Work

By John Abegglen

January 11, 2021

Of the long-term impacts COVID-19 has had on the workforce, CEOs across industries named increasing the number of employees who can work remotely as being among the most significant in a recent survey by The Conference Board.

It might seem that manufacturing industries don’t factor into that equation because so much manufacturing work doesn’t work remotely. Fifty-three percent of 558 manufacturing companies surveyed by the National Association of Manufacturers in early March said they anticipated having to make changes in their operations over the coming months, including accommodating work-from-home requests. They also said they’d have to implement business continuity response plans that include curtailed travel, restricted face-to-face interactions and staggered shifts on the shop floor to help compensate for higher than normal absences. Some field service personnel are quarantining in hotels for 12 to 14 days on both ends of on-site customer support trips.

In making these operational shifts, IIoT technologies have taken center stage — moving from being nice-to-haves to absolute necessities. What’s more, having been tested under extreme circumstances over the last several months, processes engineers who were initially hesitant to conduct remotely are now more confident. Their placed value in delivering cost-savings and efficiency gains exceeded expectations by their pivotal role in business continuity.

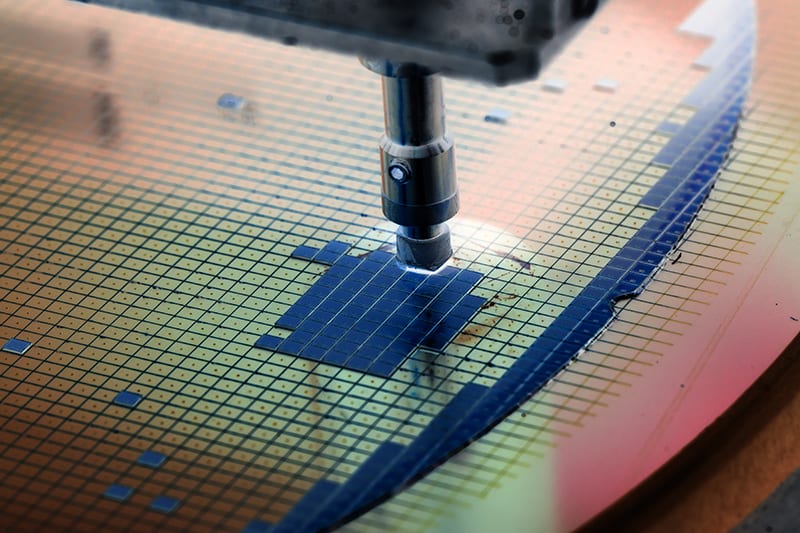

Take the application of IIoT technology in the semiconductor industry, for example. Semiconductor fabrication equipment and processes are incredibly costly. For many years, the industry’s economic realities have pushed it to find ways to minimize downtime and optimize production. As a result, it was an early adopter of IIoT technologies to enable predictive maintenance and optimize asset performance management.

Throughout the COVID-19 pandemic, companies within the semiconductor space have seen a massive increase in the time spent on IIoT applications and the number of people accessing them, particularly when it comes to remote tool operation (RTO), real-time monitoring and e-diagnostics.

The e-diagnostics lead at one semiconductor fabrication plant said far more people are accessing the system for longer times — as much as a 44% increase from February to June. He credits this to increased confidence in using the system for processes that used to take place only on-site, such as remote access to calibration and recipe editing.

The benefits of RTO extend to those working physically in the plant because the technology enables greater adherence to social distancing and travel restrictions. With RTO, processes within the fabrication plant can be accomplished much faster — in seconds, rather than minutes or hours — reducing the shop floor’s density.

Moreover, due to the high cost of equipment in the semiconductor industry, it’s common to send a team of people to install or maintain equipment (it’s difficult to turn a wrench through a network connection). Remote diagnostic capabilities have helped solve travel restriction problems while simultaneously enabling more social distancing because fewer people are on-site. One company gave the example that an engineer was able to troubleshoot a downed piece of equipment entirely from home. A process engineer at that same company went so far as to say that operations would have “ground to a halt” without RTO.

The percentage of those in manufacturing who can currently work remotely is higher than one may think. According to the Bureau of Labor’s analysis, 36.4% of manufacturing roles have the ability to telework — some 31.6% of those who can work remotely spend a significant amount of time doing so.

As employment in the industry continues to grow (manufacturing employment increased by 66,000 in September according to data from the Bureau of Labor), increased use of IIoT technologies can continue to open new frontiers of remote work in an industry vital to the economy.

Telit secureWISE® provides a way for machine owners and builders to collaborate remotely to improve equipment performance, maximizing uptime and protecting all parties’ intellectual property. secureWISE allows toolmakers to secure remote monitoring and infrastructure to mediate equipment with complete auditing capabilities. To learn more about what Telit secureWISE can do for your business, book a consultation.