Easing Industrial IT and OT Integration: A Case Study

By Bill Dykas

October 8, 2024

Estimated reading time: 5 minutes

A global automobile manufacturer wanted to make it easier and less expensive to maintain and integrate PLC devices into its MES. The company first looked for a solution based on Open Platform Communication (OPC). It reasoned that easing the process of adding new device drivers would speed up projects and ease data access.

The manufacturer ended up with a mixed model that didn’t provide the flexibility and agility it needed. Engineers still had to write custom code for MES and PLC integration, which slowed the implementation of new projects.

Moreover, the response time was slow because there was data build-up in transit. The architecture wasn’t flexible, and the software struggled to scale to support large and smaller plant implementations.

Instead, the technology added complexity and failed to:

Connected plant floor devices to the enterprise is an issue that spans industries. How can you quickly and cleanly get PLC data into MES and ERP systems? How will you orchestrate and integrate the data once it’s there?

Mapping devices like PLCs to applications is challenging. You can’t solve this problem by leveraging an OPC-based interface. Custom coding causes project backlog, which increases:

APIs and standard protocols will never eliminate custom programming. Programmers must write custom code because there are no native drivers.

Instead, organizations need a data-centric platform that provides native drivers to ensure plug-and-play functionality. This solution allows PLCs to talk to other PLCs and communicate directly to MES and ERP applications. With this functionality, you can launch IIoT projects in a matter of days, not months.

Organizations can leverage a data-centric IIoT platform that moves beyond OPC to connect legacy and modern devices regardless of communication protocol. This platform enables them to provide a central data pipeline to all devices and applications on the network.

Moreover, the IIoT middleware serves as an IT and OT application control center. It manages how, when and where data is used and quickly onboards new devices.

A flexible IIoT platform allows legacy equipment to integrate with modern systems. Many manufacturers want to adopt emerging technologies like AI and robotics. However, they cannot afford to convert all legacy systems at once, especially when older equipment still works well.

An IIoT platform that integrates IT and OT and allows old and new equipment to function and collect data. It streamlines the path toward Industry 4.0.

This solution simplifies building any logic without custom programming. With no-code or low-code functionalities, plant engineers and subject matter experts can create custom data dashboards. In addition, they can customize a deployment without requiring programmers to make the changes. This ability easily enhances device connection speed and directs the flow of data.

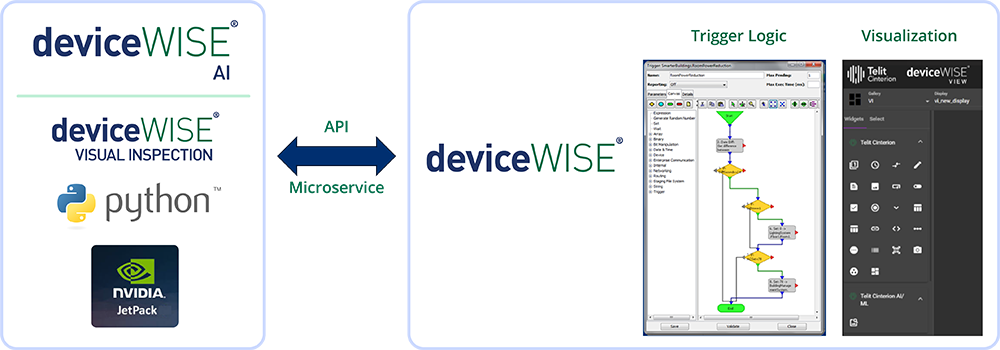

With the addition of evolving AI technologies, manufacturers can incorporate edge tools, including:

As AI models develop, manufacturing systems can learn through experience and training from human workers. This training will increase their accuracy in spotting anomalies and anticipating equipment failures before they cause downtime.

With the deviceWISE® IIoT platform, powered by Telit Cinterion, the automobile manufacturer brought together systems with a proprietary MES on a DB2 database. These systems included:

The deviceWISE platform provided a common interface to the factory floor. It didn’t present any of the performance issues presented by the OPC-based interface. The company can integrate devices to MES systems using web and messaging services for its large and small plants.

Complex business logic is now available to the plant device, and complex ladder logic has been masked. Configuring logic is less expensive. Enterprise users can access data without impacting PLC device performance.

For instance, a user may want to look at a part’s serial number history to see if it has been installed or to ensure no defect. The company wanted to ensure these activities did not impact PLC scan rates on the enterprise side.

From a factory floor perspective, that history had to be retained inside the equipment in the past. Adding more data to the PLC device slows the overall scanning time.

With deviceWISE, query capabilities enable search within the enterprise system. Leveraging web services, the organization could move some complex equipment logic into the enterprise system to ensure high performance. This speeds up the decision-making process and provides more decision-making capabilities on data at the machine level. IT support doesn’t have to increase while production and data grow.

The deviceWISE platform allows devices and apps to communicate. It provides connectivity that breaks through complicated layer transfers and a fast time to value. Implementing IoT empowered the manufacturer to focus on what it does best — making innovative vehicles.

Speak with our experts to see what our IIoT platforms with edge capabilities can do to integrate IT and OT for your enterprise.

Editor’s Note: This blog was originally published on 12 October 2018 and has since been updated.