How IoT Is Transforming the Supply Chain

By Bill Dykas

June 25, 2024

Estimated reading time: 5 minutes

Securing the supply chain has become a focal point for manufacturers. Ninety-three percent of manufacturers surveyed by McKinsey & Company will focus on supply chain resilience, especially in a crisis.

A critical influence was the COVID-19 pandemic. It caused disruption in the supply chain and left manufacturers at significant risk. This disruption exposed vulnerabilities for overseas suppliers. These vulnerabilities included increasing shipping costs and unexpected delays in single-source supply chains.

Many manufacturers want to move sourcing and manufacturing from offshore to onshore or nearshore. However, Industry 4.0, which consists of intelligent digital technologies in manufacturing, is making this complex move possible.

Another driver in reshoring is intelligent digital technologies, especially automation. Standardized open-architecture automated systems allow compatibility with software from multiple vendors.

Risks to single-source supply chains can be eliminated. Warehouse automation operations leverage robots that work on factory floors with humans to enhance efficiency and safety.

Virtual reality (VR) and augmented reality (AR) technologies enable remote assistance and enhanced visualization for supply chains. They offer immersive and interactive experiences to improve maintenance and quality control.

Reshoring will be challenging. Manufacturers must adopt the best and most advanced technologies to overcome these challenges. In addition to automation, the Internet of Things (IoT) and artificial intelligence (AI) improve efficiency and speed for more resilient supply chains.

Manufacturers can leverage IoT to connect their machinery, equipment and devices. This creates a web of interconnected systems for real-time data exchange and analysis. AI-driven predictive analytics uses historical and real-time data to:

These can help to revolutionize how manufacturers manage their supply chains and optimize production processes. Digitization can significantly increase efficiency and reduce costs if properly implemented across an entire organization.

On the other hand, when deploying this type of technology, not all companies succeed. Managing huge numbers of machine protocols and digital information is very complex. There can be challenges with analyzing which functions should be supported by what management systems.

Questions arise regarding the optimal deployment location for enterprise resource planning or supply chain management systems. Should they be situated at the edge, on the manufacturing site or in the cloud? Security issues also must be considered.

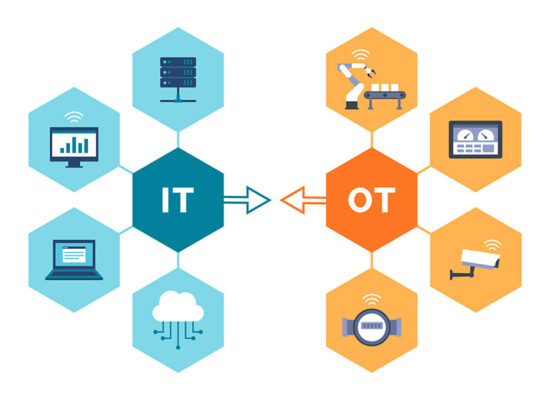

Manufacturing plants have two sides. One is operational technology (OT). OT involves systems that control and monitor physical equipment, such as machinery and devices.

The second is information technology (IT), which encompasses digital information. IT includes computer hardware, software, network infrastructure, storage, and cloud computing.

OT and IT are often independently managed as they have different management personnel, architectures and protocols. It’s equally complex to integrate both on top of new and legacy systems.

Since they have different languages and processes, there is often a communication gap between IT and OT teams. In addition, their networks are either not up to date or not sufficiently connected.

deviceWISE®, powered by Telit Cinterion, bridges that gap between OT and IT. This platform helps all your factory machines and applications “talk” to one another without custom code. This platform makes it easy to connect and translate data from the factory floor and legacy machinery through older protocols.

Many manufacturing facilities must take a hybrid cloud approach. Some data goes to the cloud, other data stays on site in the local data center or at each individual machine. With deviceWISE, you can easily extract data at the edge. It can transform the data and send it anywhere.

Smart factories leverage technologies such as automation and data exchange. The goal is to drive greater productivity and responsiveness in the supply chain. Smart factories create interconnected, data-driven production environments using IIoT systems.

Applications and benefits include:

Successful supply chain management hinges on tracking materials and products from production to delivery. IoT empowers organizations to achieve this visibility by creating smart supply chains.

IoT-enabled supply chains improve production while enhancing product safety during transit. In all cases, increasing productivity directly impacts a business’s profitability and performance.

Being successful in adopting IIoT includes people, processes and machines. Lantech changed how businesses package and protect their products for shipment. They invented the stretch wrapper to reduce shipping damage.

Lantech also has a full line of equipment, including case and tray handlers and pallet conveyors. The company also provides global sales and technical support. Stretch wrapping secures billions of pallet loads each year.

Lantech discovered several customer needs, from uptime to environmental impacts. They partnered with Telit Cinterion to create their first IoT-driven software as a service (SaaS), called Lantech Intelligent Network Connection® (LINC®). It’s powered by Telit Cinterion’s deviceWISE® platform, IoT connectivity plans and services, and cellular LTE modules.

LINC® allows subscribers to receive alerts, while data visibility enables them to monitor machine data and real-time performance from anywhere. With LINC, Lantech can improve system uptime and quality with greater productivity. At the same time, they are reducing financial and environmental costs.

Real-time information delivery can boost OEE. One of Telit Cinterion’s customers is a major tractor manufacturer. After deploying deviceWISE, they saw a 30% improvement in their OEE .

Real-time data empowers quicker decision-making while eliminating the need to wait until the end of the day or month to assess productivity. This immediacy enables teams to address issues on the production line and prevent disruptions proactively.

AI is critical for Industry 4.0 applications in manufacturing, especially for improving automation. deviceWISE AI, powered by Telit Cinterion, allows companies to deploy effortlessly on any premises or cloud environment.

It empowers users to configure a customized dashboard and workflows. It also connects external communications with programmable logic controllers (PLCs) and manufacturing execution systems (MESs) to optimize manufacturing processes. The solution delivers an end-to-end system that is easy to set up without custom code.

deviceWISE AI Visual Inspection is a versatile software solution that uses AI to make industrial-level visual inspections easy. AI and machine learning (ML) can be trained to identify complex and subtle defects that are challenging for humans to detect.

Advanced AI algorithms (e.g., YOLOv8 and Autoencoder) can recognize and categorize objects while pinpointing unusual patterns. Visual Inspection can increase efficiency and quality while reducing costs.

To overcome supply chain complexities, you must partner with experts in Industry 4.0, IoT and AI. Telit Cinterion’s mission is to simplify supply chain and manufacturing technology deployments and make them more cost-effective.

We’ve been in the IoT business for over 23 years. We develop software and platforms that allow your teams to focus on making systems work together. Our IoT platforms are prebuilt with brand-specific device drivers and enterprise integration connectors. We also support the transition to next-generation IoT solutions without custom coding.

Speak with our experts to prepare your manufacturing plant for industrial IoT and future-proof intelligent digital solutions.