Solve IoT Prototype Challenges with Modular Design

July 8, 2025

Estimated reading time: 5 minutes

Developing a functional Internet of Things (IoT) product presents challenges. Companies face pressure to validate their concepts quickly. They must ensure hardware and software compatibility while maintaining costs.

The road to a successful prototype is riddled with obstacles. Here are five hurdles companies must overcome:

Processes like custom hardware design and radio frequency (RF) engineering can add months to development. Product design and requirements definition must be agreed upon. Materials sourcing and testing take time. Any delay in the product launch schedule affects costs and impacts a business’s top line through missed sales opportunities.

Custom IoT board design is costly and takes time. Creating an IoT solution from scratch requires investment in a printed circuit board (PCB) design and compliance certification. Materials must be sourced. Sample IoT prototypes need to be designed, produced and approved by stakeholders.

Requirements may also change during the development cycle. Customers might seek to address new or additional use cases or eliminate features to save money. In each case, developers must test and retest designs until the desired product performance is consistently achieved.

Compatibility issues can arise when attempting to ensure seamless communication. Sensors and connectivity modules do not always work smoothly with cloud services. Coordinating access to the product’s intended environment — both technological and physical — ensures timely feedback and resolution of potential challenges.

It is critical to work in close communication and coordination with site personnel. Any issues that complicate setup or operation can delay troubleshooting.

Meeting regulatory requirements is expensive and time-consuming. Common regulations include:

Many IoT prototypes function in a lab but struggle at scale. Issues can be due to challenges like:

These hurdles can leave companies stuck in the prototype phase for months or even years. With each product launch delay, the risk of market obsolescence increases.

IoT developers need a streamlined process to build and test their solutions and move them from concept to production. The key is to eliminate the time-consuming barriers that slow down traditional IoT development:

A modular approach with ready-to-deploy hardware reduces costs. Precertified modules and off-the-shelf solutions shorten the development timeline. Companies can then test market viability before scaling.

Using precertified modules ensures smooth network integration and faster time to market. They can simplify RF design, regulatory approvals and carrier certification. This accelerates development and offers flexibility for future upgrades.

Sensor and connectivity integration can be complex. Plug-and-play sensor integration and standardized application program interfaces (APIs) help streamline development. Development kits with standardized interfaces allow for rapid IoT prototyping without extensive hardware modifications.

Prototyping should include a clear path to cloud integration. This ensures data transmission and remote monitoring work from day one. Smooth transitions from prototype to deployment are enabled by solutions with:

Scalable solutions that support low-volume prototyping and high-volume production prevent costly redesigns. The best solutions begin with off-the-shelf hardware but transition seamlessly to cost-optimized designs as volumes grow. Start with off-the-shelf hardware and transition to chip-down designs to reduce per-unit costs while ensuring a smooth production ramp-up.

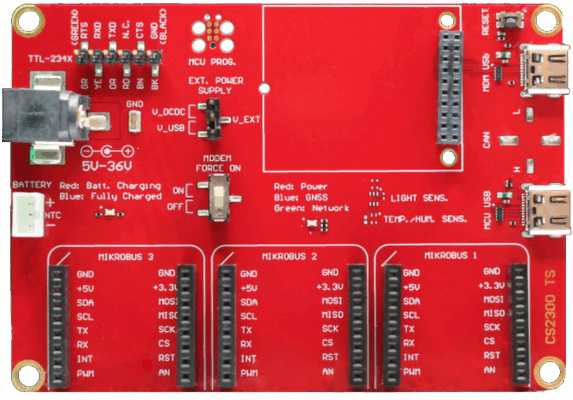

Telit Cinterion’s CMB100 series is designed to eliminate the typical bottlenecks in IoT development. With a precertified, multitechnology module, it allows companies to:

The CMB100 development kit’s precertified hardware allows engineers to build and test prototypes without the need to design from scratch. This reduces time to market and accelerates innovation cycles.

The built-in mikroBUS™ socket on our development kit allows fast, plug-and-play integration of a wide range of sensors and Global Navigation Satellite Systems (GNSS) modules. This widely adopted standard simplifies hardware development and accelerates prototyping through the:

Avoid the certification headache with pretested carrier approvals. The CMB100 comes precertified for global cellular networks, eliminating the need for time-consuming compliance testing. Businesses can focus on deployment rather than regulatory challenges. LTE Cat M, Cat 4 and Cat 1 bis ensure seamless data transmission and reduced capability (RedCap) 5G network support.

Many IoT projects start with low-volume production before scaling to mass deployment. The CMB100 platform is flexible.

Companies can begin with a module-based design and transition to a chip-down architecture. This optimizes costs at higher production volumes. Businesses can scale efficiently without the need to redesign their entire solution.

With simplified IoT prototyping, companies eliminate integration risks and go to market faster while reducing costs. Developers can focus on innovation instead of troubleshooting.

Successful IoT prototyping requires:

Companies can reduce their time to market if they streamline development through:

Telit Cinterion’s CMB100 series is built to support this journey, enabling businesses to innovate with confidence.

Speak with our IoT experts to learn how the CMB100 can help you develop your rapid prototype.