Overcoming AI and IoT Manufacturing Integration Challenges

By Bill Dykas

November 21, 2024

By Bill Dykas

November 21, 2024

Estimated reading time: 4 minutes

The manufacturing industry is a leading Internet of Things (IoT) solution adopter. Use cases that demonstrate significant return on investment and justify the high adoption include:

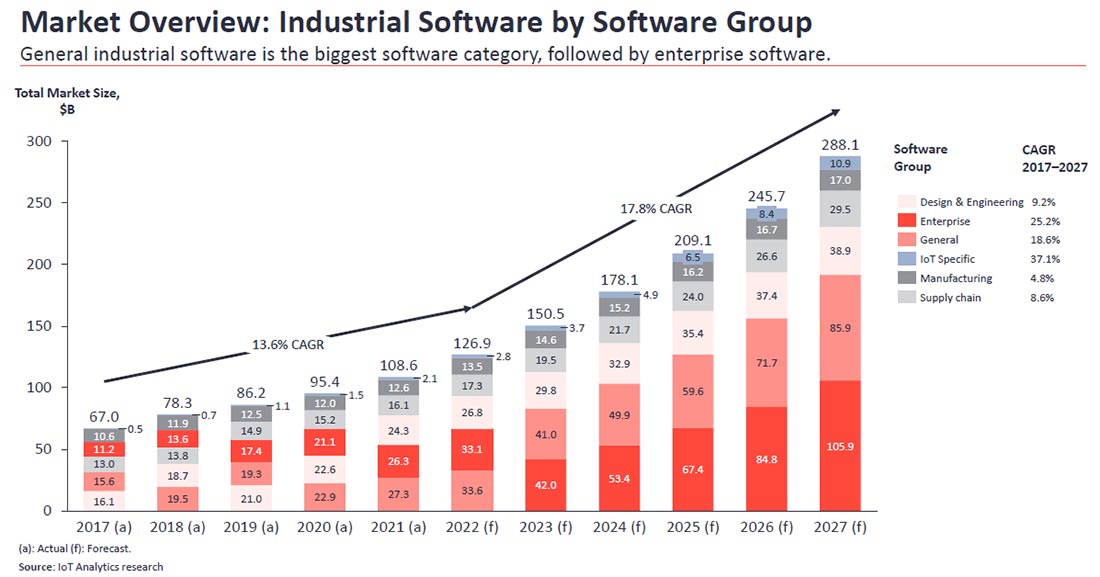

A report from IoT Analytics says that IoT software will grow by 37% in the industrial software market. This increase is expected to happen between 2022 and 2027.

The manufacturing industry is also keen on integrating artificial intelligence (AI) solutions and adopting data-capturing technology like sensors and cameras. AI enhances the performance of vision inspection systems. It allows businesses to go from manual inspections to automated data-capturing processes.

This data links with existing enterprise resource planning (ERP) and cloud platforms for data analysis. This enables manufacturers to make data-driven decisions and streamline their operations.

IoT and AI are essential components of digital transformation for manufacturing enterprises. Nevertheless, adding these technologies to manufacturing processes can be difficult, with the most prominent challenges being enterprise application integration, scalability and security.

Scalability comes in two forms:

Achieving digital transformation is only possible for manufacturing companies if they can scale their complex processes. Scaling requires standardization across multiple plants, lines and machines. To that end, manufacturers must consider these three C’s:

Commonality describes the need for a single IoT management system between machines and IT systems. However, many machines in the manufacturing industry speak different languages. These machines need to be on the same page for operations and processes to scale.

Manufacturers can standardize their machines’ communication by deploying a platform like deviceWISE®, powered by Telit Cinterion. This industrial IoT (IIoT) platform has the industry’s largest list of equipment connectors and languages. It allows machines and IoT devices to speak to each other.

Clonability refers to the ability to reuse programming. Scaling custom code is unrealistic. However, with deviceWISE, manufacturers can replicate a project, moving line to line and factory to factory, promoting similitude across applications.

Cost-effectiveness ensures that the total cost of ownership (TCO) is affordable in relation to what the manufacturer wants to scale. deviceWISE replaces many layers in these manufacturing environments, decreasing TCO.

Manufacturers have dozens of machines and software solutions, each with unique APIs and connectors. Given this, commonality is required when integrating machine data into an IT system.

Manufacturers can use deviceWISE to create an abstract layer that can collect data from any machine. This platform creates metadata that can integrate with any IT system, including:

deviceWISE ensures that the data from IoT devices and AI-powered machines integrates seamlessly with enterprise system data.

As manufacturers look to scale their solutions, adding layers of security to IoT devices and networks is critical. Research from a leading security operations company reveals that manufacturing was the third most represented in ransomware engagements. It was fourth most represented in email compromise engagements.

The rise in connected IIoT devices has opened the door for cybercriminals to exploit these devices. They can infiltrate organizations’ critical systems and steal sensitive data. Manufacturers must follow best IoT security practices, including:

Some top concerns surrounding IoT in the manufacturing industry are:

These concerns are linked to an organization’s ability to scale its IoT deployment. They can perform this expansion by adding devices or bottom-to-top integration with back-office systems. Manufacturers must work with proven vendors and service providers to alleviate these challenges. They should find companies like Telit Cinterion that have existing use cases in deploying IoT solutions in the industry.

Manufacturers should also avoid using large customer code applications. These restrict flexibility and drive up TCO, which makes integrating AI and IoT applications difficult.

deviceWISE allows manufacturers to develop and deploy solutions with plug-and-play modules. They can scale and integrate deployments over time. Manufacturers can add devices, disparate systems and cloud management capabilities smoothly and without custom code.

deviceWISE is a vertically integrated platform that will deliver the technical components you need for digital transformation. deviceWISE AI eliminates the hassle of custom programming. This solution empowers manufacturers to add AI and machine learning to IoT applications cost-effectively and at scale. Speak with our experts to learn how deviceWISE can help your business utilize AI in IIoT.

Editor’s Note: This blog was originally published on 12 June 2018 and has since been updated.