IIoT Systems Management: Unlocking IoT in Manufacturing

By Bill Dykas

October 29, 2024

Estimated reading time: 4 minutes

We have heard Industry 4.0 technologies and the industrial Internet of Things (IIoT) will improve the manufacturing industry. To date, the focus is on data acquisition and how to digitize the factory. However, the big picture about how to use the data is a mystery.

We can more closely monitor the factory line for signs of upcoming component failure or causes of quality issues. Still, how can IoT benefit the overall enterprise and supply chain?

Bill Dykas, senior product manager of IoT platforms for Telit Cinterion, shared insights with Automation World on the following:

With over 20 years of experience in IIoT systems management, he has helped numerous companies benefit from IoT.

Collecting data for the sake of collecting data does not achieve anything. It must be aimed at solving an issue or opportunity in the factory, larger business unit or supply chain.

Identifying a problem that an IoT integration should fix is key to understanding:

Another gap is capturing data intelligently at a sampling rate that makes sense. Then, summarized data can be stored, when appropriate, in a form that upstream and downstream processes can utilize. Why sample and store a temperature value every five seconds when the value doesn’t change?

Sometimes, the biggest obstacle is moving beyond one piece of equipment or line into the larger business. There are always technical obstacles, but those are always solved.

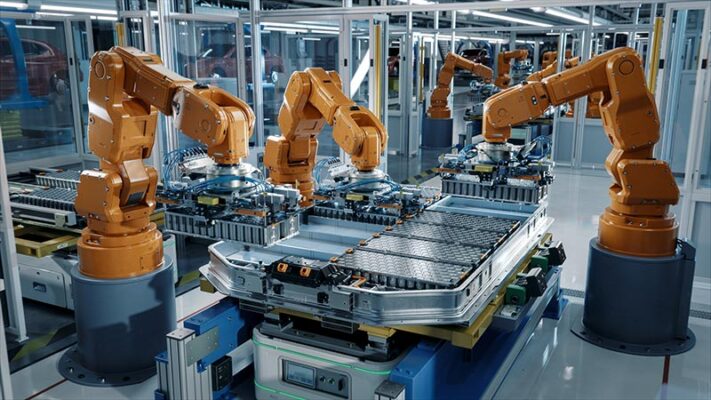

Factory automation, robots and control systems are well known and in place today. The next level is taking the equipment-generated data and tying it back to the business application. That is the biggest obstacle — and the biggest opportunity.

Some of the most interesting things are what you do with the data from the business side. This takes imagination. Integrating data from manufacturing systems with data from external sources expands IoT’s value on the supply chain and business unit.

Capturing fault data for drives or other devices and automatically uploading it to the vendor allows the vendor to optimize their drive’s performance and failure rate. This improves uptime for factories and benefits the whole sector.

Pick a specific process or issue to improve and do a mini proof of concept (POC) project. This focuses IoT integration into a smaller project with better-defined metrics that are easier to measure.

The specific process is not as important as gaining experience from a successful POC and getting buy-in from management to expand the project.

The exact process is less important than gaining experience from a successful POC. It is also crucial to get management’s support to expand the project.

Security is at the top of everybody’s mind because of ransomware attacks. We can see increased attacks as we move OT and IT into the cloud.

It is often overlooked because you focus on transporting data from point A to point B. How can you ensure the data is correct? Also, how do you know the right asset sends the data securely on the network?

These questions are fundamental. We will see that focus and transformation in the next few years, which I think has lacked in the last five to six years.

Speak with a Telit Cinterion expert to discover how an IIoT systems management program can benefit the factory and the larger manufacturing business.

Editor’s Note: This blog was originally published by Automation World and has since been updated.