Increase Industrial Productivity with AI Visual Inspection

By Bill Dykas

December 18, 2024

By Bill Dykas

December 18, 2024

Estimated reading time: 3 minutes

Artificial intelligence (AI) has revolutionized industries worldwide. One of its most important applications is in industrial visual inspection. Visual inspection tools for the industrial Internet of Things (IIoT) automate and improve defect detection and component verification.

Quality control methods that rely on manual inspections and processes are time-consuming and prone to errors. In contrast, AI-powered visual inspections can:

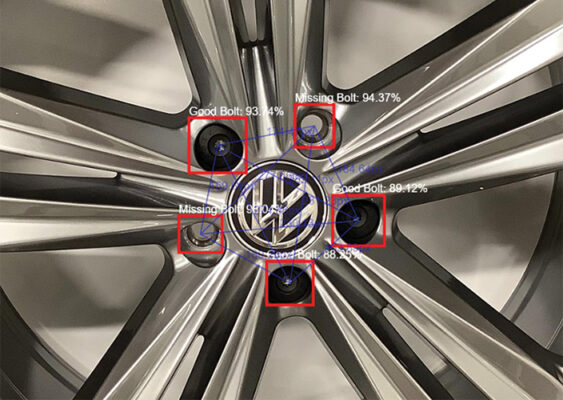

AI visual inspection systems use advanced machine learning algorithms to analyze images and detect anomalies. Compared to manual inspections, AI visual inspection platforms provide higher accuracy and speed.

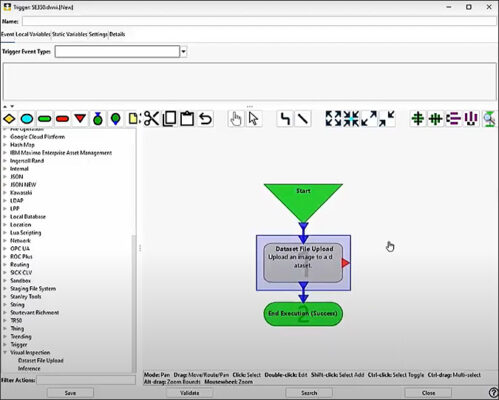

Visual inspection solutions empower manufacturers with a no-code, user-friendly interface. They can build inspection models in a few clicks. Training these models to recognize defects and patterns requires annotated images to create a file that can infer real-time results. Once trained, these models can execute workflows, issue corrective actions and log results in real time.

In addition, these no-code interfaces make deploying industrial visual inspection solutions fast and easy, only taking a few hours. These tools allow users to:

Companies can rapidly implement visual inspection solutions without extensive programming expertise. With one-click installation scripts, these platforms can be deployed on various systems. These range from on-premises, enterprise-grade servers to cloud platforms or edge devices like NVIDIA® Jetson® boards.

AI visual inspection systems support and integrate seamlessly with devices, such as:

These tools also communicate with relational databases and business systems (e.g., SAP and IBM Maximo). This ensures that data flows smoothly between operational processes and enterprise management.

AI can transform quality assurance by:

These systems can inspect products at various assembly stages and flag issues before they become problems. They also perform energy loss inspections using infrared cameras, contributing to operational efficiency.

Beyond quality, AI visual inspection systems are crucial for safety and logistics as they can:

AI-powered visual inspection platforms adapt to varying needs. Their adaptability enables them to scale from handheld devices to large enterprise-grade servers with GPUs. This makes them suitable for companies of all sizes, from small businesses to global enterprises.

Central to this technology is the deviceWISE® AI Visual Inspection platform, powered by Telit Cinterion. This solution provides advanced AI algorithms with an intuitive interface to streamline efficiency and improve product quality. It empowers businesses across industries with an end-to-end inspection system they can set up without custom code.

deviceWISE AI is changing how businesses transform operations by improving automation and decision-making. Reducing downtime and boosting quality assurance can help companies enhance performance and remain competitive. Speak with our IIoT experts to discover what deviceWISE AI Visual Inspection can do for your company.