Automotive Manufacturing and Industry 4.0: 2 Case Studies

By Bill Dykas

May 29, 2025

Estimated reading time: 3 minutes

Artificial intelligence (AI) and Industry 4.0 have been part of the automotive sector for years. Innovators combined these technologies with big data to cut costs through improved quality and production.

Automotive manufacturers can transform their facilities into smart production plants with a top industrial IoT (IIoT) platform. Leading business digitalization platforms offer:

These platforms can locate the source of a serious quality problem or increase productivity by analyzing data.

The number of parts in a car can vary between 30,000 and 40,000, depending on the vehicle’s make and model. The simplest defect in a part can have serious implications and delay production. Automotive manufacturers always look for solutions that minimize downtime and safeguard production schedules.

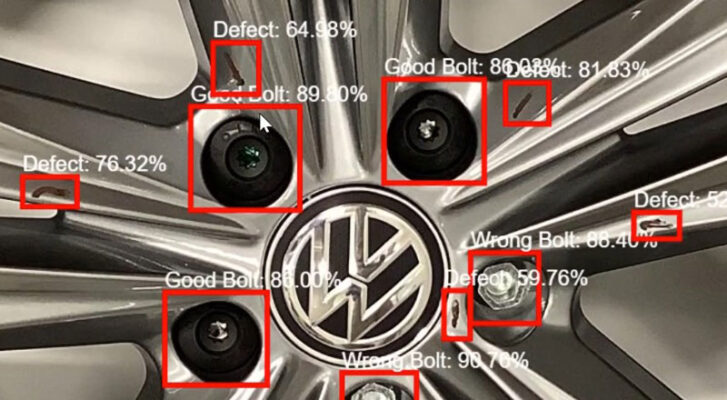

One leading IoT platform includes a suite of AI applications — a versatile software solution for visual inspection. This AI-powered application uses advanced algorithms and deep learning to find problems and solve issues in real time.

Manufacturers train the inference engine. Powered by AI and machine learning (ML), it identifies defects humans often miss. It ensures accurate results and reduces errors to maximize productivity.

A common application of this visual inspection solution is checking assembled components. For example, inspecting wheels for missing or damaged lug nuts. Cameras take pictures of vehicles’ wheels as they proceed along the production line. These photos go through the IoT platform and then to the inference engine.

The inference engine analyzes the images and creates a markup that indicates the condition of the lug nuts. Edge communication sends the data to a system that generates a trouble ticket if needed.

Best-in-class offerings provide configuration of customized dashboards and external communications with PLCs, clouds and MESs. Leading visual inspection solutions integrate seamlessly with industrial equipment and software systems.

Automobile factories contain arrays of equipment. Companies need real-time analytics about their machines and the data they generate to avoid downtime and boost uptime. However, data is not useful unless connected to a business application.

A metalworking and metal fabrication machine manufacturer has thousands of large, expensive machines in customers’ factories worldwide. The manufacturer introduced a remote monitoring solution to supply customers with 24/7 production line monitoring. An IoT platform powers the solution. It includes edge software and a cloud-based subscription service.

Customers’ machines connect to the IoT provider’s cloud via edge software. The cloud sends data to the machine tool manufacturer’s application. Customers receive collected machine health and performance data so they can view their machines’ real-time statuses.

The solution features remote diagnostics and fault monitoring for quick intervention to reduce downtime and on-site visits. Moreover, the IoT platform integrates seamlessly with the machine tool manufacturer’s existing system’s architecture.

Automotive manufacturers desire solutions to digitize their processes. Taking their production offline to install a new system is daunting. Over time, they must update and change equipment, including inference (AI) data applications, which causes downtime.

deviceWISE®, powered by Telit Cinterion, is a transparent, overarching solution that tracks and integrates data in a single portal.

Incorporate existing devices and automation systems with:

We can work with any system architecture to connect all your devices and apps using native drivers. Our platform lets you connect multiple facilities to compare data across the enterprise. Best of all, you can access everything through a single interface.

Don’t take your production line down for an overhaul. Let Telit Cinterion provide seamless integration of a transparent IoT and AI automotive manufacturing solution.

Editor’s note: This blog was originally published on 4 October 2018 and has since been updated.